Nantong Wuzhou Composite Material Co.,Ltd

Tel:0513-80570785

Fax:0513-80570781

Adress:No.8, Zhengtong Road, Yuanqiao Industrial Park of Rugao, Jiangsu, China

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections.

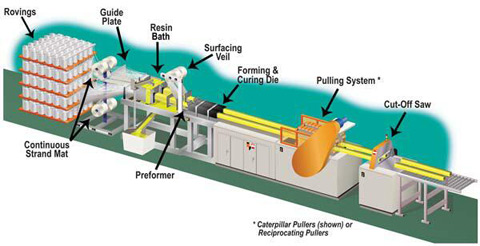

The reinforcement materials are in continuous forms such as rolls of fiberglass mat and doffs of fiberglass roving. As the reinforcements are saturated with the resin mixture ("wet-out") in the resin bath and pulled through the die, the gelation, or hardening, of the resin is initiated by the heat from the die and a rigid, cured profile is formed that corresponds to the shape of the die. While pultrusion machine design varies with part geometry, the basic pultrusion process concept is described in the schematic shown below.